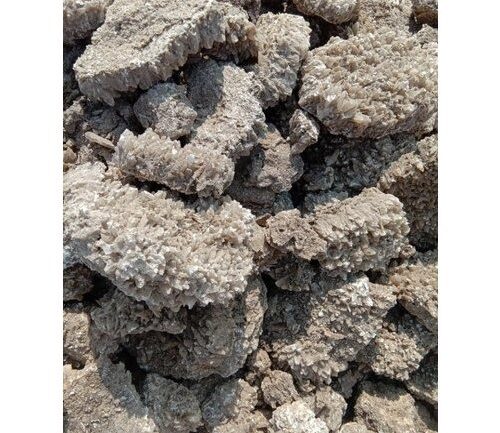

Gypsum

Gypsum is a soft sulfate mineral composed Of calcium sulfate dihydrate, with the chemical formula CaS04•2H20. It is a by product of Solar Salt Farming process and it is widely used in cement manufacturing industry, fertilizer industry and as the main constituent in many forms of plaster, drywall and blackboard or sidewalk chalk.

We provide both Washed and Unwashed gypsum with quality standards as required by our clients.

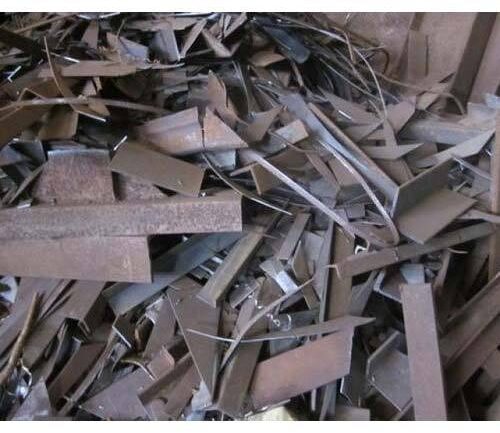

MS & HMS Scrap

HMS scrap (also known as heavy melting steel scrap) and mild steel scrap are both types of recycled steel that are used in a variety of applications. However, there are some key differences between the two. HMS scrap is made up Of heavier, thicker pieces of steel that are typically more durable and resistant to wear. It is often used to make new steel products that require strength and durability. Mild steel scrap, on the other hand, is made up of thinner, lighter pieces of steel that are not as strong or durable as HMS scrap. It is Often used to make products that do not require as much strength or durability.

We deal with various steel manufacturers and are capable of supplying 1000 MT of HMS or MS scrap every month as per the quality standards and stock demands of our clients.

Mill Scale

Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are being produced by rolling red hot iron or steel billets in rolling mills. Mill scale is bluish-black in color. Mill scale can be used as a raw material in granular refractory. When this refractory is cast and preheated, these scales provide escape routes for the evaporating water vapor, thus preventing cracks and resulting in a strong, monolithic structure. Rolling mill scale is a complex oxide that contains around 70% iron with traces of nonferrous metals and alkaline compounds. The reduced iron powder may be obtained by converting the mill scale into a single highest oxide i.e. hematite (Fe203) and its reduction with hydrogen.

We provide the best quality of Mill scale as required by our clients for both domestic use and export purposes.

Granulated Blast Furnace Slag (GBFS)

Blast furnace slag is a nonmetallic by-product produced in the process of producing iron in the blast furnace. It consists primarily of silicates. aluminosilicates. and calcium-alumina-silicates. The molten slag, which absorbs much Of the sulphur from the charge, comprises about 20 percent by mass of iron production. If the molten slag is cooled and solidified by rapid water quenching to a glassy state, little or no crystallization occurs. This process results in the formation of sand size (or frit-like) fragments, usually with some friable clinkerlike material. The physical structure and gradation of granulated slag depend on the chemical composition of the slag. Its temperature at the time of water quenching, and the method Of production. When grinded to very fine cement-sized particles, grounded granulated blast furnace slag (GGBFS) has

cementitious properties, which make a suitable partial

replacement for or additive to Portland cement.

We are capable of supplying a bulk quantity of 50,000 MT per month. sourced from the best steel or iron manufacturing industries of Gujarat.

Ground Granulated Blast Furnace Slag (GGBFS)

GGBFS (Ground Granulated Blast-furnace Slag) is a cement-like material whose main use is in Concrete and Slag Cement manufacturing. It is made from the by-product of the blast- furnaces used to make iron.

We are capable of supplying 3000 MT per month to our clients.

We adhere to the best quality standards at all times. Fineness

of the product can be achieved as per clients requirements. We

provide Bulk, 50KGs and 1.5MT packaging sizes.

Iron Ore – Fine & Lumps

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow,

or deep purple to rusty red. The products offered by us are of very fine quality. Our mined products have rich content of iron(Fe 45-63%) as a result the users get relatively high amount of iron.

Fly Ash

Fly ash produced during the burning of powdered coal in thermal power plants is a hazardous waste. However, its physical and chemical properties make it an ideal raw material for producing high quality and cost-effective bricks, interlocking pavers, kerbstones and mosaic tiles. Fly ash can be used in portland cement concrete to enhance the performance of the concrete.

Fly ash can also be used for construction of road and embankment.

We at “KBM Enterprises” are quality cautious and reliable supplier for cost effective supply of Fly Ash to Indian market as well as exports. We offer F & C Class Fly Ash, and Wet/Pond fly ash.

Gallery

Gypsum

Marine Gypsum – Washed

Gypsum

Marine Gypsum – Unwashed

Iron Ore

Iron Ore – Fine

Iron Ore

Iron Ore – Lumps

Scrap

MS & HMS

Scrap

MS & HMS

Scrap

MS & HMS

Scrap

Mill Scale

Ash

Fly Ash

Slag

GBFS

Slag

GGBFS

Scrap

Rubber Tyre – Shredded

Scrap

Rubber Tyre – Shredded

Scrap

Rubber Tyre – Whole

Scrap

Rubber Tyre – Whole

Scrap

Rubber Tyre – Whole